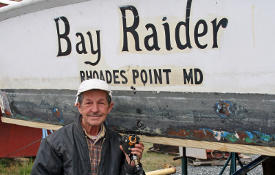

Traditional Boatwright Leland F. Helmstetter, Jr.

by

Down the Eastern Shore of Virginia, the numerous creeks which empty into the Chesapeake Bay are home harbors to hundreds of traditional wooden watercraft which support the watermen in their quest to derive a living harvesting the variety of resources from the Bay. The craft of choice is the versatile Deadrise Boat or Box Stem. Handmade over the years at various boatyards, these craft were handmade entirely of wood. Most are approximately 40 feet long with a large open work area in the stem and a small-enclosed pilothouse in the bow.

Servicing these boats is an ongoing process as the wooden hulls are prone to rot and the damage caused by the ever-present wood worms, which bore a labyrinth of tunnels that weaken the hull. Repair and replacement of this woodwork falls to a select few with specific knowledge of the construction techniques handed down from many generations of true boatwrights.

Deep Creek, Virginia is home to several watermen who still work the Chesapeake Bay. Here you will find the Deep Creek Marina and Boatyard operated by Karl and Andrea Wendley. With a 25-ton open-end travel lift they are capable of servicing most any size vessel. Here pleasure craft mingle with many traditional watermen's boats. The ship's store is a friendly gathering place for most of the residents of this charming community. Just outside, I am introduced to Leland F. Helmstetter, Jr., who was in the process of replacing the aft hull planks of "Bay Raider", a 40-foot box stern owned by Eddie Landon. The Bay Raider had fallen victim to an infestation of wood worms and sank stem first in Cape Charles harbor. She was "floated and pumped out, towed to Deep Creek, hauled out using the Wendley's travel lift and blocked.

At 65 years of age, Homey, as Mr. Helmstetter is known in the Region, scrambles around beneath the blocked boat with the agility of a wrestler. At first glance, the arrangement of hydraulic jacks supporting posts, which apply pressure on hull planks,looks random and somewhat chaotic.

Homey explains "the white pine must be cut in winter so's the sap is down." This allows the greatest contortions forced on the wood to conform to the shape of the hull frame and do it permanently. He orients each plank with the grain arching downward to provide the greatest strength. A copious amount of thick tar is smeared at contact points with the hull frame and adjoining planks. With the precision of a piano tuner he jacks the supports to gently and evenly coax the hull planks into position to conform to the exact shape of the hull. It is a long and tedious process and cannot be rushed, move the wood too fast and it will crack the grain and create a weak spot. When he is satisfied with the position of the plank, he uses a specific tool to drive stainless steel ribbed nails through the plank to permanently fasten it to the frame. He then daubs some tar over the nail head and begins anew with the next plank.

Mr. Helmstetter, who calls Chesconessex, Virginia his home, began working on boats from an early age under the guidance of his father Leland, Senior. He is of the opinion that the best Bay boats were constructed in Deltaville, Virginia. His services need no advertising as he reflects there is no shortage of boats in need of repair. It is very important to him that his work contributes to the continuation of the active service of these boats in the waterman's trade. In our conversations, never did I hear him speak of the money he makes to perform his services. To him it is a genuine passion to repair these boats right, as lives depend on his skill.

Next week he will be off to another marina on the Bay to repair another wooden Box Stern. Like the dwindling resources of the Bay, Mr. Helmstetter is a member of a small fraternity of surviving traditional wood Boatwrights working to keep old boats active and a living heritage of the Chesapeake Bay.